SF6 Flange Sealing Repair.

The asset was leaking SF6 gas due to general degradation of the flange gasket. This resulted in the customer having to pay expensive fines to local authorities.

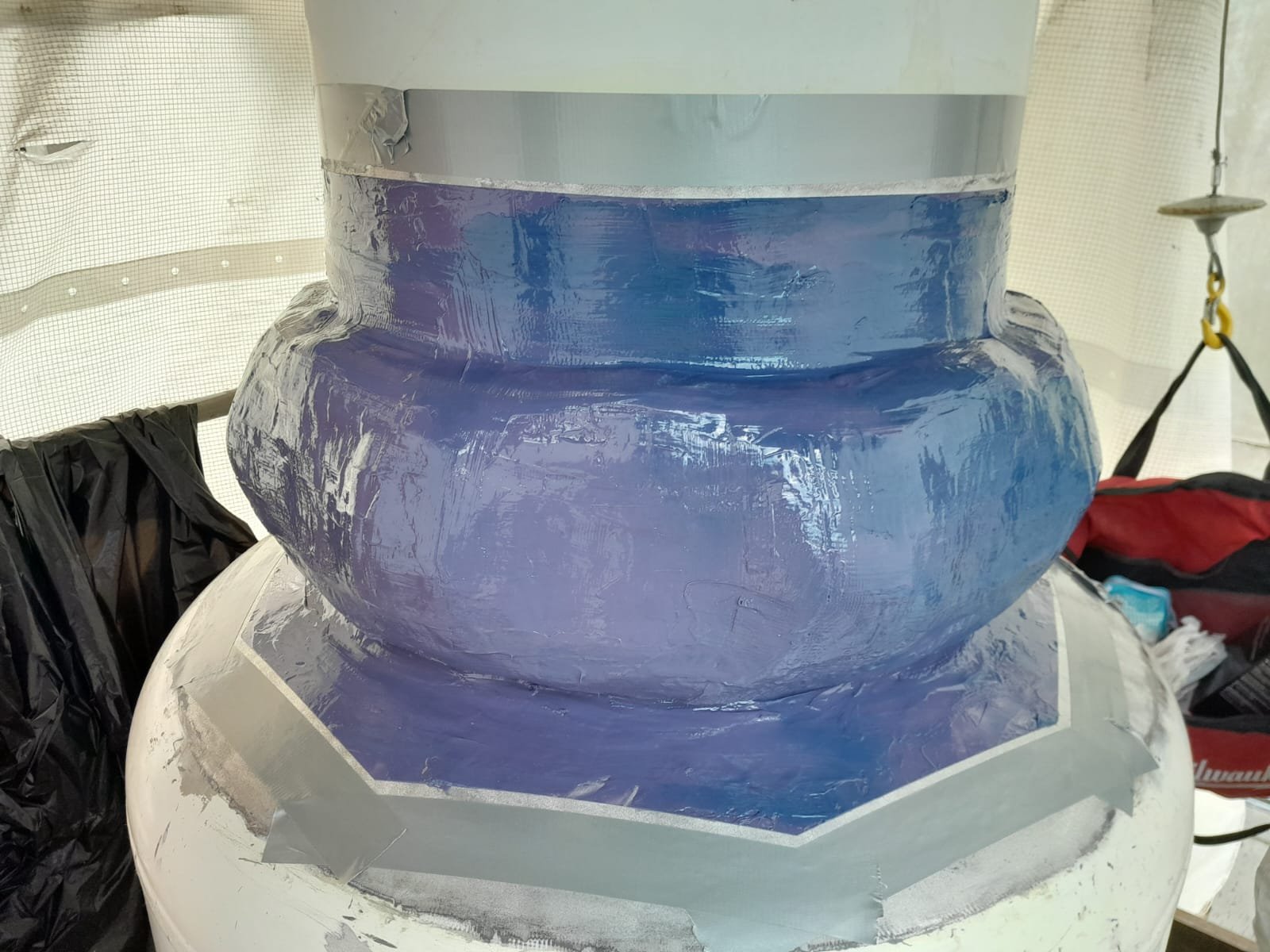

The substrate was prepared as per SSPC-SP11 standard, using an MBX Bristle Blaster to remove any oxidation from the surface and provide a rough surface profile for mechanical adhesion.

A backing-rod was applied behind the flange bolts and tape was applied over the bolts themselves (this prevents Belzona from adhering to them and allows a smoother surface transion). A Breather Membrane was applied around the circumference of the flange encapsulang it in its enrety, a Redirecon Nozzle was also fied to channel the leaking gas. Belzona 7311 was then applied to seal the membrane prior to the applicaon of the impregnated Belzona 9341 (Reinforcement Sheet). The newly applied Belzona 7311 was then weed out using Belzona 1981 (Winter Grade) SWII Resin prior to the applicaon of 5 x wraps of Belzona 9371 (SWI Reinforcement Sheet) forming 10-layers (due to the 50% overlap). This was then le to polymerise (generang a slight self-curing exotherm) prior to a final encapsulang layer of Belzona 7311.

Note: This project was undertaken whilst employed by Belzona Limited.

Client - National Grid

Location - United Kingdom

Status - Completed

Date - 09/2023